5.3 ls torque specs pdf

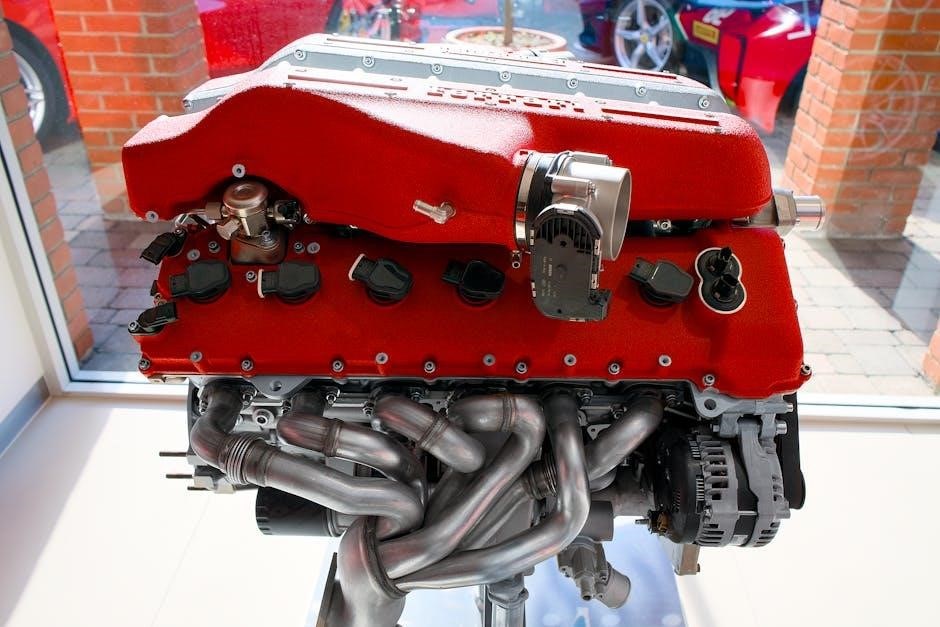

The 5.3L LS engine‚ part of Chevrolet’s Vortec series‚ is a reliable and powerful V8 engine used in various trucks and SUVs. Known for its 5.3-liter displacement‚ this engine features advanced technologies like Variable Valve Timing (VVT) and Active Fuel Management (AFM)‚ enhancing performance and efficiency. Popular for its durability and versatility‚ the 5.3L LS engine has become a favorite among enthusiasts and professionals alike‚ offering a balance of power and fuel economy.

1.1 Overview of the 5.3L LS Engine

The 5.3L LS engine is a V8 powerplant renowned for its reliability and versatility. Produced from 1999 to 2013‚ it features a 5.3-liter displacement with a 3.78-inch bore and 3.62-inch stroke; This engine utilizes an overhead valve (OHV) design with two valves per cylinder. It incorporates advanced technologies like Variable Valve Timing (VVT) and Active Fuel Management (AFM) to optimize performance and fuel efficiency. Commonly found in Chevrolet and GMC trucks and SUVs‚ the 5.3L LS engine is celebrated for its balance of power‚ durability‚ and efficiency‚ making it a popular choice for both daily driving and performance upgrades.

1.2 Importance of Torque Specifications

Torque specifications are crucial for ensuring the integrity and performance of the 5.3L LS engine. Proper torque ensures all components are securely fastened‚ preventing leaks and engine damage. Under-torquing can lead to loose connections and potential leaks‚ while over-torquing may result in stripped threads or warped parts. Adhering to specified torque values guarantees optimal sealing and prevents premature wear. Using a digital torque wrench enhances accuracy‚ and following the correct sequence and passes is vital for even force distribution and engine longevity. Accurate torque application is essential for maintaining engine performance and preventing costly repairs.

Torque Specifications for Major Engine Components

Key components like cylinder head bolts‚ main bearing caps‚ and connecting rods require precise torque values to ensure proper engine assembly and prevent damage. Always follow specified limits.

2.1 Cylinder Head Bolts

The cylinder head bolts for the 5.3L LS engine require precise torque specifications to ensure proper sealing and prevent damage. The recommended torque for the first pass is 22 lb-ft‚ followed by a final pass of 90 degrees. It is crucial to tighten the bolts in a crisscross pattern to avoid warping the cylinder head. Using a torque wrench and following the manufacturer’s sequence ensures optimal results. Always consult the factory service manual or a certified technician for precise torque values and procedures to maintain engine integrity and performance.

2.2 Main Bearing Cap Bolts

The main bearing cap bolts for the 5.3L LS engine are critical for securing the crankshaft and ensuring proper engine operation. The recommended torque specification for these bolts is 15 ft-lbs for the first pass‚ followed by an additional 80 degrees of rotation for the final pass. It is essential to tighten the bolts in the manufacturer-recommended sequence to avoid uneven stress distribution. Using a calibrated torque wrench and adhering to these specs will help maintain engine stability and prevent potential damage. Always consult the factory manual or a certified technician for precise guidance.

2.3 Connecting Rod Bolts

The connecting rod bolts on the 5.3L LS engine play a vital role in maintaining the integrity of the rotating assembly. The torque specifications for these bolts are 15 ft-lbs for the initial pass and 60 degrees for the final pass. Proper tightening sequence is crucial to ensure even loading and prevent rod bearing damage. Using a torque wrench calibrated to these specifications is essential for maintaining engine reliability. Always follow the manufacturer’s guidelines and consider consulting a certified technician for precise application. Adhering to these torque values will help ensure optimal engine performance and longevity.

2.4 Oil Pan Bolts

The oil pan bolts on the 5.3L LS engine are crucial for ensuring a leak-free seal. Torque specifications vary based on bolt size: M8 bolts require 18 ft-lbs‚ while M6 bolts are torqued to 8 ft-lbs. Additionally‚ the oil pan baffle and closeout cover bolts also require 8 ft-lbs. Proper torque application ensures the oil pan is securely fastened‚ preventing leaks and maintaining engine performance. Always use a torque wrench and follow the recommended sequence to avoid uneven stress. Adhering to these specs is vital for the engine’s longevity and optimal functionality.

2.5 Oil Drain Plug Torque Specs

The oil drain plug for the 5.3L LS engine requires a torque specification of 18 ft-lbs. Proper tightening ensures a leak-free seal and prevents damage to the oil pan threads. Using a torque wrench is essential to avoid over-tightening‚ which could strip the threads or damage the pan. Always refer to the manufacturer’s guidelines for precise specifications‚ as variations may exist depending on the vehicle application. Correct torque application is critical for maintaining the integrity of the engine’s oil system and preventing costly repairs. Adhere strictly to the 18 ft-lbs specification for optimal results.

Torque Specs for Auxiliary Components

Air conditioning compressor bolts: 37 ft-lbs‚ fuel injection fuel rail bolts: 89 lb-in‚ exhaust manifold bolts: 18 ft-lbs‚ and engine valley cover bolts: 18 ft-lbs.

3.1 Air Conditioning Compressor Bolts

The air conditioning compressor bolts on the 5.3L LS engine require precise torque to ensure proper installation and functionality. The recommended torque specification is 37 ft-lbs. This ensures the compressor is securely fastened without over-tightening‚ which could damage the mounting bracket or threads. Proper torque is essential for maintaining the integrity of the A/C system‚ preventing leaks and vibrations. Always use a torque wrench to achieve the exact specification‚ and refer to the manufacturer’s guidelines for any specific instructions or variations. This step is crucial for optimal performance and longevity of the engine and its components.

3.2 Fuel Injection Fuel Rail Bolts

The torque specification for the fuel injection fuel rail bolts on the 5.3L LS engine is 89 lb-in. Proper tightening is essential to ensure a leak-free seal and prevent damage to the fuel system. Using a torque wrench is recommended to achieve the exact specification. Over-tightening can lead to stripped threads or warped surfaces‚ while under-tightening may result in fuel leaks and reduced engine performance. Always follow the manufacturer’s guidelines for specific instructions‚ as variations may exist depending on the engine’s configuration and year. Adhering to the recommended torque specs is vital for maintaining the integrity of the fuel injection system.

3.3 Exhaust Manifold Bolts

The torque specification for the exhaust manifold bolts on the 5.3L LS engine is 18 lb-ft. Proper tightening ensures a secure seal and prevents leaks. Use a torque wrench to apply the specified torque in a star pattern to avoid warping the manifold. Over-tightening can damage threads or the manifold‚ while under-tightening may lead to exhaust leaks and reduced performance. Ensure bolts are clean and free of debris before tightening. If replacing gaskets‚ follow the manufacturer’s recommendations for installation. Proper torque application is critical for maintaining the integrity of the exhaust system and overall engine efficiency.

3.4 Engine Valley Cover Bolts

The torque specification for the engine valley cover bolts on the 5.3L LS engine is 18 lb-ft. Proper tightening ensures a secure‚ leak-free seal. Use a torque wrench to apply the specified torque evenly. Over-tightening can damage the cover or threads‚ while under-tightening may lead to leaks. Clean the bolts and surface before installation. If replacing the gasket‚ ensure it is properly seated. Following the manufacturer’s torque specs is essential for maintaining engine performance and preventing potential issues. Always torque bolts in the recommended sequence to avoid uneven stress on the cover.

Engine Configuration and Design

The 5.3L LS engine features a V8 configuration with a displacement of 5.3 liters (325 cubic inches). Its overhead valve (OHV) design includes two valves per cylinder. Known for its durability‚ the engine utilizes Variable Valve Timing (VVT) and Active Fuel Management (AFM) to optimize performance and efficiency. With a bore of 3.78 inches and stroke of 3.62 inches‚ this engine has been a staple in GM trucks and SUVs from 1999 to 2014‚ delivering reliable power and versatility.

4.1 V8 Configuration and Displacement

The 5.3L LS engine features a V8 configuration‚ with a total displacement of 5.3 liters (325 cubic inches). This design provides a balance of power and efficiency‚ making it ideal for trucks and SUVs. The engine’s bore measures 3.78 inches‚ and the stroke is 3.62 inches‚ contributing to its robust performance. The V8 layout ensures smooth operation and consistent power delivery‚ while the displacement size supports both everyday driving and heavy-duty applications. Its compact yet powerful design has made it a popular choice for Chevrolet vehicles‚ offering versatility and reliability across various models.

4.2 Overhead Valve (OHV) Design

The 5.3L LS engine utilizes an Overhead Valve (OHV) design‚ where the valves are located in the cylinder head‚ operated by a camshaft in the engine block. This configuration simplifies the engine structure‚ reducing complexity and potential mechanical failures. The OHV design enhances combustion efficiency and allows for a more compact engine layout. It contributes to the engine’s reliability and fuel efficiency‚ making it a popular choice for trucks and SUVs. This design also supports the engine’s balance of power and economy‚ ensuring optimal performance across various applications.

4.3 Variable Valve Timing (VVT) and Active Fuel Management (AFM)

The 5.3L LS engine incorporates advanced technologies like Variable Valve Timing (VVT) and Active Fuel Management (AFM). VVT adjusts valve timing to optimize power and efficiency across the RPM range‚ while AFM deactivates cylinders during light load conditions to reduce fuel consumption. These systems work seamlessly‚ providing improved fuel economy without sacrificing performance. AFM transitions between 8-cylinder and 4-cylinder modes effortlessly‚ ensuring smooth operation. Together‚ VVT and AFM enhance the engine’s adaptability‚ making it highly efficient and versatile for various driving conditions.

Oil Service Intervals and Recommendations

The 5.3L LS engine requires regular oil changes using 5W-20 or 5W-30 synthetic oil for optimal performance. Service intervals are every 7‚500 miles or 12 months.

5.1 Recommended Oil Specifications

The 5.3L LS engine requires high-quality engine oil to ensure optimal performance and longevity. The recommended oil viscosity is 5W-20 or 5W-30 synthetic oil‚ which provides superior lubrication and protection in extreme temperatures. Using synthetic oil is highly recommended for its enhanced thermal stability and wear resistance. The oil capacity for the 5.3L LS engine is approximately 6 quarts with a new filter. Always use oil that meets GM’s Dexos1 specification for compatibility and performance. Regular oil changes with the correct viscosity and specification will help maintain engine health and fuel efficiency.

5.2 Oil Change Intervals

The recommended oil change interval for the 5.3L LS engine is every 7‚500 miles or 12 months‚ whichever comes first. Regular oil changes are crucial for maintaining engine health and performance. Use synthetic oil meeting GM’s Dexos1 specification for optimal lubrication. Replace the oil filter during each service to ensure proper filtration. Exceeding the recommended interval can lead to increased wear and potential engine damage. Adhere to this schedule to keep your 5.3L LS engine running smoothly and prolong its lifespan.

5.3 Importance of Oil Quality for Engine Longevity

Using high-quality oil is essential for the longevity and performance of the 5;3L LS engine. Always select oil that meets GM’s Dexos1 specifications to ensure proper lubrication and protection against wear. Synthetic oils are recommended for their superior thermal stability and viscosity consistency. Inferior oils can lead to premature wear‚ increased emissions‚ and reduced fuel efficiency. Regular oil changes with quality products help maintain the engine’s health‚ prevent sludge buildup‚ and ensure optimal performance over time‚ making it a critical part of routine maintenance.

Tools and Equipment for Torque Applications

Essential tools for torque applications include a digital torque wrench‚ extension bars‚ and calibration equipment. A digital wrench provides precise control for accurate torque and angle specifications.

6.1 Digital Torque Wrenches

Digital torque wrenches are essential for precise torque applications. They offer preset torque and angle modes‚ ensuring accuracy for critical engine components. These tools provide real-time monitoring‚ audible alerts‚ and data logging‚ reducing errors. High-quality models‚ like the Snap-On digital wrench‚ allow users to set specific torque values and track progress. Digital wrenches are more reliable than mechanical ones‚ offering better control and consistency. They are indispensable for achieving the exact torque specs required for components like cylinder head bolts and connecting rods‚ ensuring engine longevity and performance. Proper use prevents over-torquing and under-torquing‚ safeguarding against damage.

6.2 Torque Wrench Calibration and Maintenance

Regular calibration and maintenance of torque wrenches are critical for ensuring accuracy and reliability. Digital torque wrenches should be calibrated annually or as specified by the manufacturer. Before use‚ inspect the tool for damage or wear. Store torque wrenches in a protective case to prevent damage. Always use the wrench within its specified torque range to maintain accuracy. Proper maintenance includes cleaning the tool and ensuring all moving parts function smoothly. Calibration should be performed by a certified technician or according to the manufacturer’s guidelines to ensure precise torque applications for engine components.

Common Mistakes to Avoid During Torque Applications

- Ignoring manufacturer guidelines for torque specifications.

- Improper torque sequence leading to uneven stress.

- Over-torquing or under-torquing bolts‚ risking damage.

7.1 Improper Torque Sequence

Improper torque sequence is a common mistake that can lead to uneven stress distribution across engine components. For the 5.3L LS engine‚ tightening bolts in the wrong order can result in warped surfaces or damaged threads. Cylinder head bolts‚ for instance‚ must be tightened in a crisscross pattern to ensure even clamping force. Similarly‚ main bearing cap bolts require a specific sequence to maintain crankshaft alignment. Deviating from the recommended sequence can compromise engine integrity and lead to costly repairs. Always refer to the manufacturer’s guidelines for the correct tightening sequence.

7.2 Over-Torquing and Under-Torquing

Over-torquing and under-torquing are critical errors that can damage engine components. Over-torquing can strip threads or warp surfaces‚ while under-torquing may result in loose connections‚ leaks‚ or premature wear. For the 5.3L LS engine‚ exceeding specified torque values can lead to head gasket failure or cracked cylinder heads. Conversely‚ insufficient torque may cause bolts to loosen over time‚ compromising engine performance and safety. Always use a torque wrench and adhere to manufacturer guidelines to avoid these issues and ensure proper component seating and sealing.

7.3 Ignoring Manufacturer Guidelines

Ignoring manufacturer guidelines for torque specifications can lead to severe engine damage and premature wear. Proper torque values ensure components are securely fastened without over-stressing parts. Deviating from these guidelines risks stripped threads‚ cracked components‚ or gasket failure. Always refer to the official torque specs for the 5.3L LS engine to maintain reliability and performance. Neglecting these recommendations can compromise engine longevity and lead to costly repairs. Adhering to manufacturer guidelines is essential for optimal engine function and durability.

Additional Resources and References

Consult Chevrolet’s official manuals‚ online forums like LS1Tech‚ and certified technicians for detailed torque specifications and expert advice on the 5.3L LS engine.

8.1 Manufacturer Manuals and Guides

Manufacturer manuals and guides are essential resources for accurate torque specifications and installation procedures. Chevrolet and GM provide detailed documentation for the 5.3L LS engine‚ including torque values‚ bolt sequences‚ and tightening procedures. These manuals ensure compliance with factory standards‚ preventing damage and ensuring proper engine assembly. They often include charts and diagrams for clarity. Additionally‚ GM’s service manuals cover oil service intervals‚ part specifications‚ and diagnostic tips. Consulting these official resources before starting any project is highly recommended for reliability and safety.

8.2 Online Forums and Communities

Online forums and communities are invaluable for discussing torque specifications and sharing experiences with the 5.3L LS engine. Platforms like LS1Tech‚ Reddit’s r/LSX‚ and specialized car enthusiast forums offer extensive discussions on torque specs‚ installation tips‚ and common mistakes to avoid. Members often share PDF guides‚ personal insights‚ and real-world applications‚ providing practical advice beyond official manuals. These communities foster collaboration‚ allowing users to learn from others’ experiences and gain confidence in their projects. They are a vital resource for both professionals and DIY enthusiasts working on the 5.3L LS engine.

8.3 Certified Technician Recommendations

Certified technicians emphasize the importance of adhering to manufacturer torque specifications for the 5.3L LS engine. They recommend using a calibrated torque wrench and following the correct bolt tightening sequence to ensure proper sealing and prevent damage. Regular maintenance‚ such as oil changes and inspections‚ is also crucial for longevity. Technicians advise against over-torquing‚ as it can lead to stripped threads or warped components. Consulting the official service manual or a trusted repair guide is highly recommended for precise torque values and procedures. Their expertise ensures reliable and efficient engine performance.

Adhering to proper torque specifications ensures optimal performance and longevity for the 5.3L LS engine. Regular maintenance and correct bolt tightening sequences are essential for reliability and efficiency.

9.1 Summary of Key Torque Specifications

The 5.3L LS engine requires precise torque specifications for optimal performance and longevity. Key components include cylinder head bolts at 22 lb-ft (first pass) and 90 degrees (final pass)‚ main bearing cap bolts at 75 lb-ft‚ and connecting rod bolts at 15 lb-ft (first pass) and 60 degrees (final pass). Oil pan bolts are torqued to 8 ft-lbs (M6) or 18 ft-lbs (M8)‚ while the oil drain plug is set at 18 ft-lbs. Adhering to these specifications ensures proper sealing‚ prevents damage‚ and maintains engine reliability. Always follow manufacturer guidelines for accurate torque applications.

9.2 Final Tips for Engine Maintenance and Performance

Regular oil changes‚ using high-quality filters‚ and adhering to torque specifications are crucial for the 5.3L LS engine’s longevity. Always use the recommended oil viscosity and follow the manufacturer’s service intervals. Avoid over-tightening or under-tightening bolts‚ as this can lead to engine damage. Inspect components like the oil drain plug and valve cover gasket for signs of wear. Properly torque all bolts in the specified sequence to ensure even pressure distribution. For optimal performance‚ consider upgrading to synthetic oil and monitoring engine temperatures. Follow the owner’s manual for specific guidance to maintain peak performance and reliability.